Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

AC Battery Cable Manufacturer: Ensuring Reliable Power Connections for Your Projects

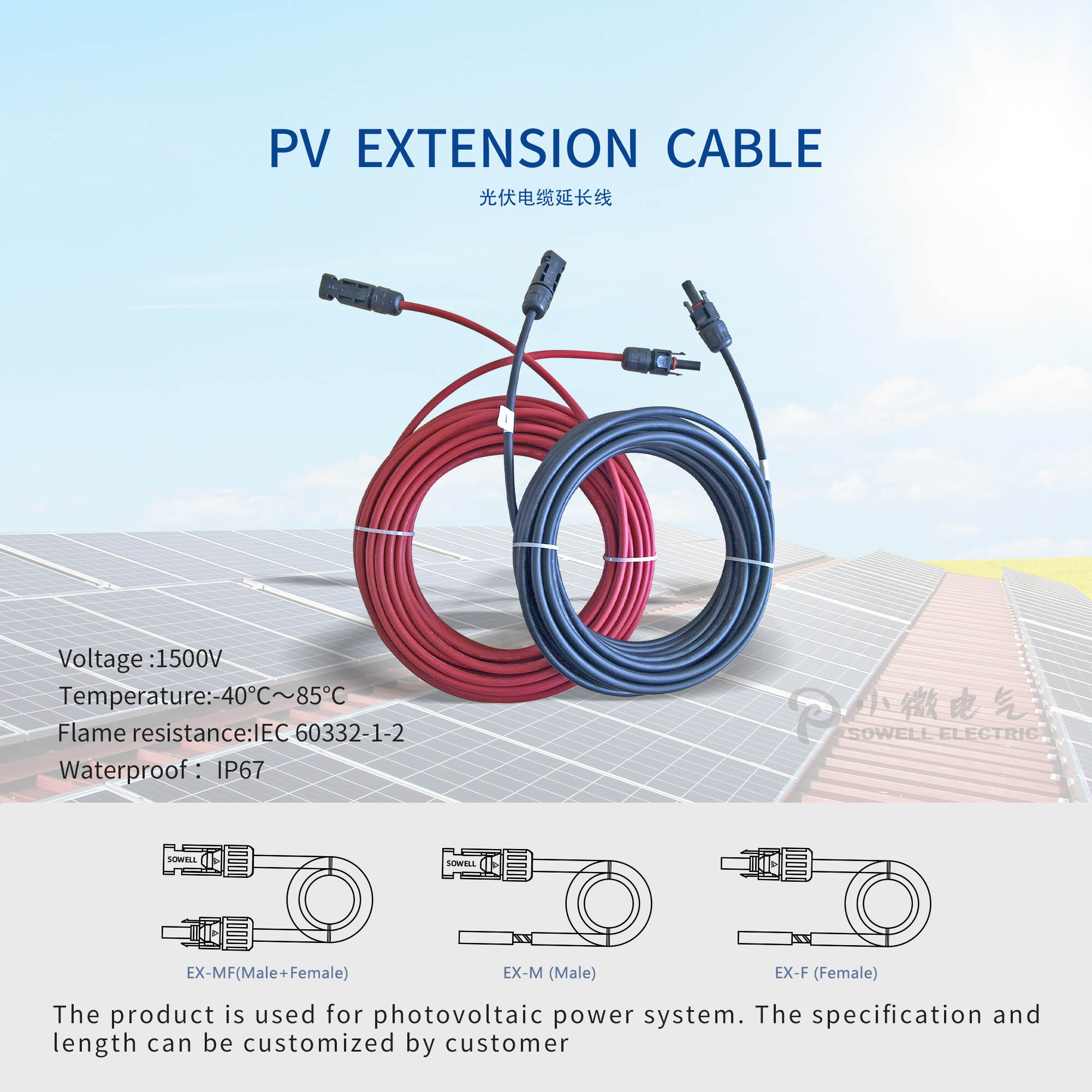

In today’s rapidly evolving electrical and energy industries, the role of a trusted AC battery cable manufacturer has never been more critical. Whether for industrial applications, renewable energy systems, or automotive setups, having high-quality AC battery cables ensures safety, efficiency, and longevity of your electrical systems. Choosing the right manufacturer can significantly influence the performance and reliability of your entire power infrastructure.

Understanding AC Battery Cables

AC battery cables are specifically designed to handle alternating current (AC) applications, providing a secure connection between power sources and loads. Unlike standard electrical wiring, these cables must meet rigorous standards for voltage tolerance, insulation, and thermal resistance. A reputable AC battery cable manufacturer will ensure that each cable meets international certifications, guaranteeing both safety and compliance.

These cables are essential in a wide range of applications:

-

Industrial machinery: Powering heavy-duty equipment with stable AC voltage.

-

Renewable energy systems: Connecting inverters, solar panels, and batteries for efficient energy conversion.

-

Automotive and marine setups: Ensuring reliable energy transfer in vehicles and boats.

Why Quality Matters

Selecting the right AC battery cable manufacturer is crucial because low-quality cables can cause overheating, voltage drops, and even electrical fires. Manufacturers who prioritize high-grade copper conductors, advanced insulation materials, and precise engineering processes will provide cables that not only perform well but also last longer.

High-quality AC battery cables offer:

-

Superior conductivity: Reducing energy loss and improving efficiency.

-

Durable insulation: Protecting against abrasion, chemical exposure, and temperature fluctuations.

-

Reliable performance: Maintaining consistent power flow under demanding conditions.

Innovations in AC Battery Cable Manufacturing

Leading AC battery cable manufacturers continuously innovate to improve cable performance. Some of the latest advancements include:

-

High-flexibility cables: Designed for applications requiring frequent bending or movement.

-

Heat-resistant insulation: Extending cable life in high-temperature environments.

-

Custom cable solutions: Tailored lengths, connectors, and specifications for specialized projects.

These innovations ensure that your electrical systems operate safely and efficiently, even under the most challenging conditions.

How to Choose the Right Manufacturer

When searching for a reliable AC battery cable manufacturer, consider the following factors:

-

Certifications and Standards: Ensure the manufacturer complies with international safety and quality standards such as UL, IEC, or ISO.

-

Material Quality: Look for high-purity copper or aluminum conductors and robust insulation materials.

-

Technical Support: A manufacturer with strong technical expertise can assist in selecting the right cable for your application.

-

Customization Options: The ability to customize cable length, thickness, and connectors can be a major advantage.

-

Reputation and Reviews: Check past client feedback and case studies to gauge reliability.

Applications Across Industries

From industrial power systems to renewable energy projects, high-quality AC battery cables are indispensable. Manufacturers often serve multiple sectors, including:

-

Solar and wind power installations

-

Electric vehicles and battery storage systems

-

Marine and aviation power distribution

-

Data centers and critical infrastructure

A trusted AC battery cable manufacturer understands the specific requirements of each industry, providing cables that meet both performance and safety standards.

Maintenance and Safety Tips

Even the best AC battery cables require proper maintenance. Regular inspection for signs of wear, corrosion, or loose connections can prevent failures. A professional AC battery cable manufacturer often provides guidance on maintenance schedules, safe installation practices, and troubleshooting tips.

Key maintenance tips include:

-

Inspect cables regularly for visible damage.

-

Ensure connectors are tight and corrosion-free.

-

Avoid exposure to excessive heat or harsh chemicals.

-

Follow manufacturer guidelines for load and current ratings.

Conclusion

Selecting the right AC battery cable manufacturer is essential for ensuring reliable, safe, and efficient power connections. From high-quality materials to cutting-edge manufacturing processes, a reputable manufacturer can provide solutions that support your project’s success. Whether you are managing industrial machinery, renewable energy systems, or automotive setups, investing in superior AC battery cables is a decision that pays off in performance, safety, and peace of mind.